Datacentre RFID set to become $1BN Market

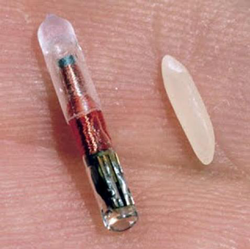

RFID chip next to a grain of rice (via Wikipedia)

This article has been contributed by Jackie Luo, CEO of E-ISG Asset Intelligence.

RFID’s application in data centres is on the way to becoming a $1 billion business. A new survey released by Frost & Sullivan says that the RFID data centre market was worth $96.3 million last year, and will grow to $953 million in 2017. The declining cost and increasing performance of RFID tags are converging at the time when IT hardware asset tracking is facing significant challenges on all fronts. A perfect opportunity for the RFID technology to expand its reach.

The value of the RFID technology to IT Asset Management is the cost savings in auditing hardware inventory. Consequently, more frequent audits of IT hardware assets are not necessary, therefore the risk of non-compliance is reduced. Applying the right kind of RFID tags suitable for the environment is the key to achieve that saving and risk management.

In general, there are three kinds of RFID tags: passive, active, and battery assisted passive tags (BAP). The emergency of BAP tags, which cost less than active tags but have a longer reading range, has the most potential for application in IT Asset Management. The performance of BAP tags is more reliable around metal objects like racks and servers. With these BAP RFID tags, one can use an RFID reader to finish inventorying a data room in a few hours instead of a few weeks. More importantly, the process is not disruptive to a normal workday, so IT departments can perform an audit more frequently. IT departments can also tag the individual devices with these types of RFID tags. That will allow them to perform spot inventory audits more frequently because of the reduced time requirement. They may not capture all the individual devices, but they will add more interim location data of these devices to the asset history.

How to take advantage of RFID

So how do IT departments best take advantage of the latest RFID technology to manage their hardware assets?

Jackie Luo

- They need to use RFID tags and other tools in combination to build and maintain an accurate hardware asset inventory.

- Get an automatic feed from the procurement system or vendor shipment record. You can connect the IT asset management system with the procurement system or vendor shipment data via web APIs, or you can set up regular import from these systems.

- Install a network auto discovery tool that will constantly report all the devices accessing the network.

- Determine which groups of hardware assets need to be tagged with RFID tags and choose the most appropriate types of RFID tags.

- Set up a periodic manual inventory audit only for exceptional items.

Ideally, IT departments will have the tools to help them reconcile the hardware data from these sources. An IT asset management solution should be able to provide these types of analysis and exception reporting, and support the workflow to reconcile the inventory data.

This article has been contributed by Jackie Luo, CEO of E-ISG Asset Intelligence.

About Guest Contributor

This post was written by a guest contributor. Please see their details in the post above. If you'd like to guest post for The ITAM Review please contact us.